DIVERSIFIED PROCESS

CNC (Computer Numerical Control) machining is one of the most essential technologies in modern precision manufacturing. By using computer-controlled toolpaths, CNC machines can produce complex components with high accuracy, consistency, and reliability.

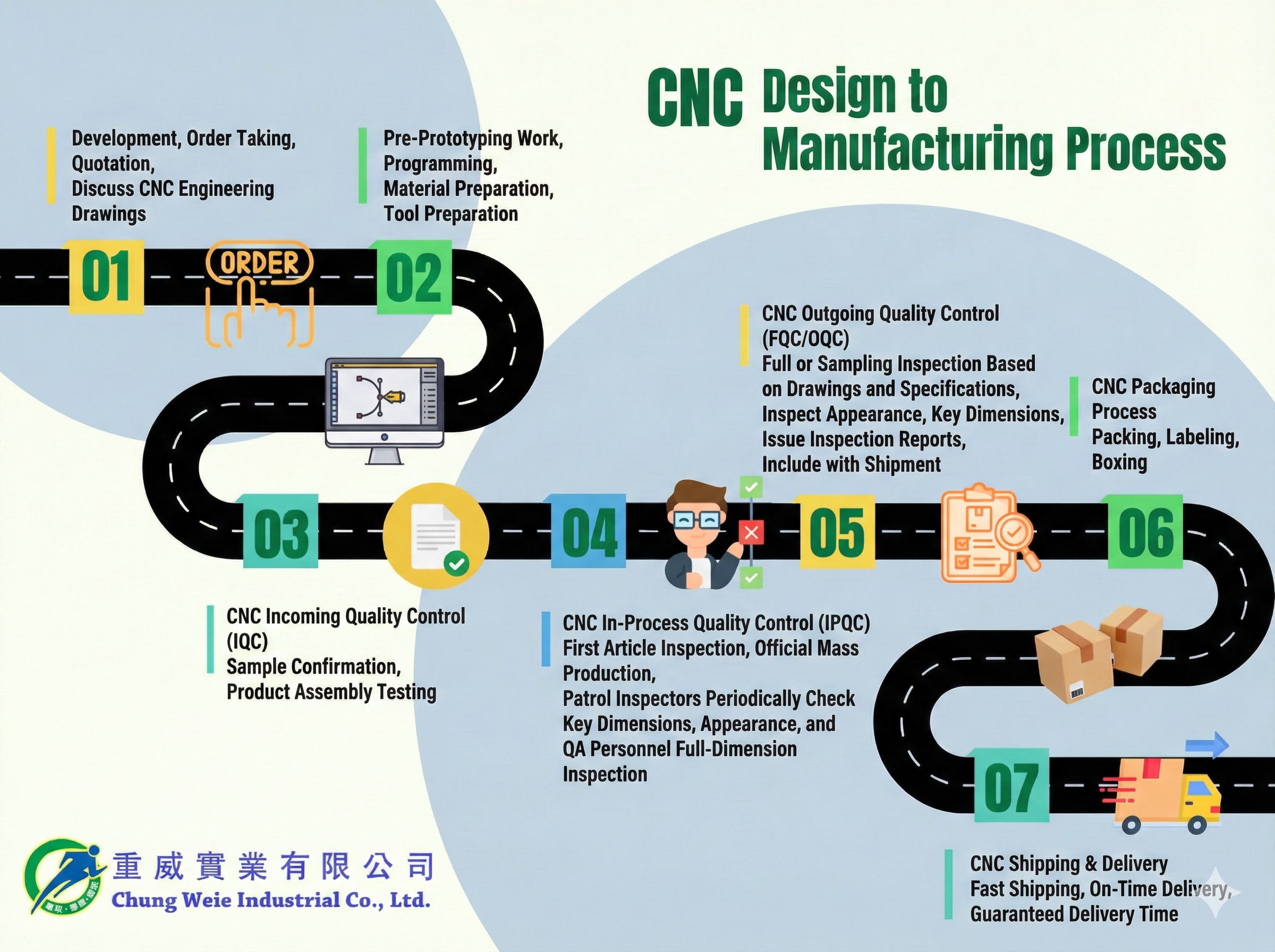

Chung Weie Industrial offers a comprehensive precision CNC machining process, integrating engineering design review, CNC programming, material inspection, in-process quality control and final inspection, to packaging and global delivery. With strict quality control standards including IQC, IPQC, and FQC inspection, we ensure high precision and consistency for custom CNC parts used in aerospace, drone, automotive and industrial applications.

Discover our end-to-end CNC machining workflow ensuring high precision, stability and quality for custom components.

CNC Machining Workflow – Chung Weie Industrial Co., Ltd.

1. CNC Engineering Review & Quotation

We start by discussing your requirements in detail, analyzing the part design and manufacturing feasibility, and providing an accurate quotation tailored to your project.

2. Pre-Production Setup: Programming & Process Planning

Based on CAD/3D models, our engineers write CNC machining programs, select tools, and prepare machining strategies to ensure efficient high-precision manufacturing.

3. IQC – Incoming Quality Control

All incoming raw materials and prototype samples undergo thorough inspection for material conformity and initial dimensional checks prior to production.

4. IPQC – In-Process Quality Control

We perform first article inspections, regular sampling and essential dimensional checks throughout production to ensure consistent quality and adherence to specifications.

5. FQC – Final Quality Control

Before shipping, all completed parts go through final inspections — either full inspection or sampling — and quality reports are generated for your records.

6. Packaging & Labeling

To protect the product during transportation, we use:

- Bubble wrap, protective film, and custom partitions

- Clear labeling and part identification

- Export-safe packaging when required

7. Shipping & Delivery

- Fast shipping

- Stable lead time

- Long-term stock and inventory support (optional)

Why Choose Chung Weie Industrial Co., Ltd.?

- Professional CNC turning-milling compound machining

- Advanced precision measuring equipment

- Strong quality control system

- Extensive machining experience with multiple materials

- Flexible production for both small and large batches

- Reliable delivery and customer support

Send us your drawings today—our team will provide a complete machining evaluation and quotation.

Get a Quote or Consultation

Need precision CNC machining services or a custom quote? Contact our engineering team for expert support, manufacturing planning, and technical guidance.